Our comprehensive range of Synthetic Belts are able to fulfil the application needs for light to heavy processing and conveying applications.

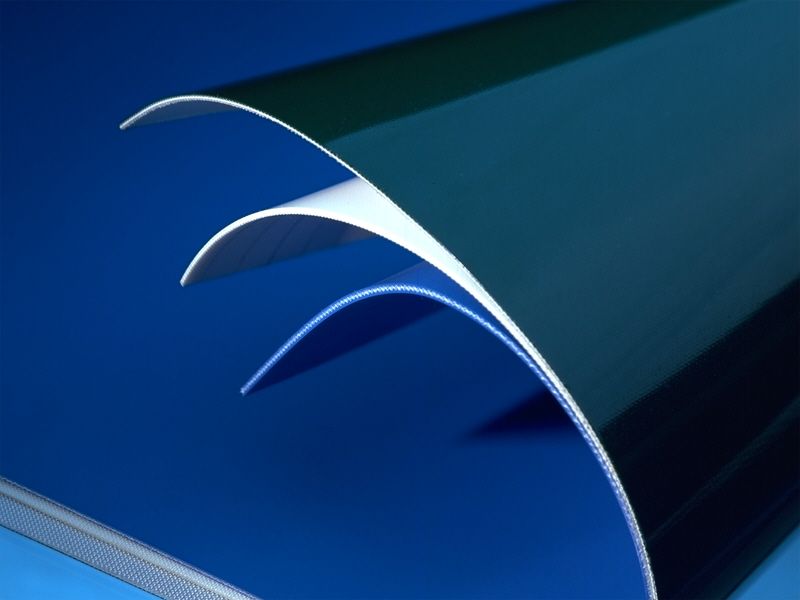

Synthetic conveyor belts are made of fabrics with a coating on the top and/or bottom side. A belt consists of one or more fabric plies to give certain features such as strength, stability and impact resistance.

Materials

The coatings used on Synthetic Belts are called polymers and can be made of various materials which have influence on the suitability of the belt in a certain application.

Polymers can be separated into two different groups: thermoplastic or thermoset.

Mainly used compounds for coatings are:

PVC | Polyurethane | Polyolefin | Polyester

Features

Synthetic Belts are produced using different materials, thicknesses, colours etc. Therefore each belt has different features such as high grip, non-fray or wear-resistance for example.

Food Grade belts are primarily used in the Food Industry and the Tobacco Industry. Flame-retardant and energy efficient belts are a sought-after feature in the Airports and Logistics Industries.

Indications of Use

There are more usages for Synthetic Belts besides the normal A-to-B (horizontal) conveying of goods, where a specific belt is needed to get the job done.

- Curved conveying

- Troughed conveyors

- Inclined or declined conveying

Fabrication & Accessories

Plain belt material is fabricated to customise the belt to your specifications, for example, cutting to the right length and width.

An important fabrication job is making the belt endless. Belts can be made endless by means of various splicing methods.

Synthetic Belts can also be fitted with accessories such as cleats (also called carriers), ropes and corrugated sidewalls.