Condensate Drains

Home/Divisions/Compressor and Vacuum Units/Condensate Drains

Condensate draining equipment is possibly the most ignored component of a compressed air system but nevertheless, a most important part. No matter how much money you wasted on high-quality equipment for compressed air (compressors, dryers, filters), compressed air quality becomes worthless, if the condensate is not discharged from the system.

Condensate in compressed air system can cause large problems (inconsistent supply of dry air will cause production problems, formation of rust, wreck the machinery, freeze-up in the winter...

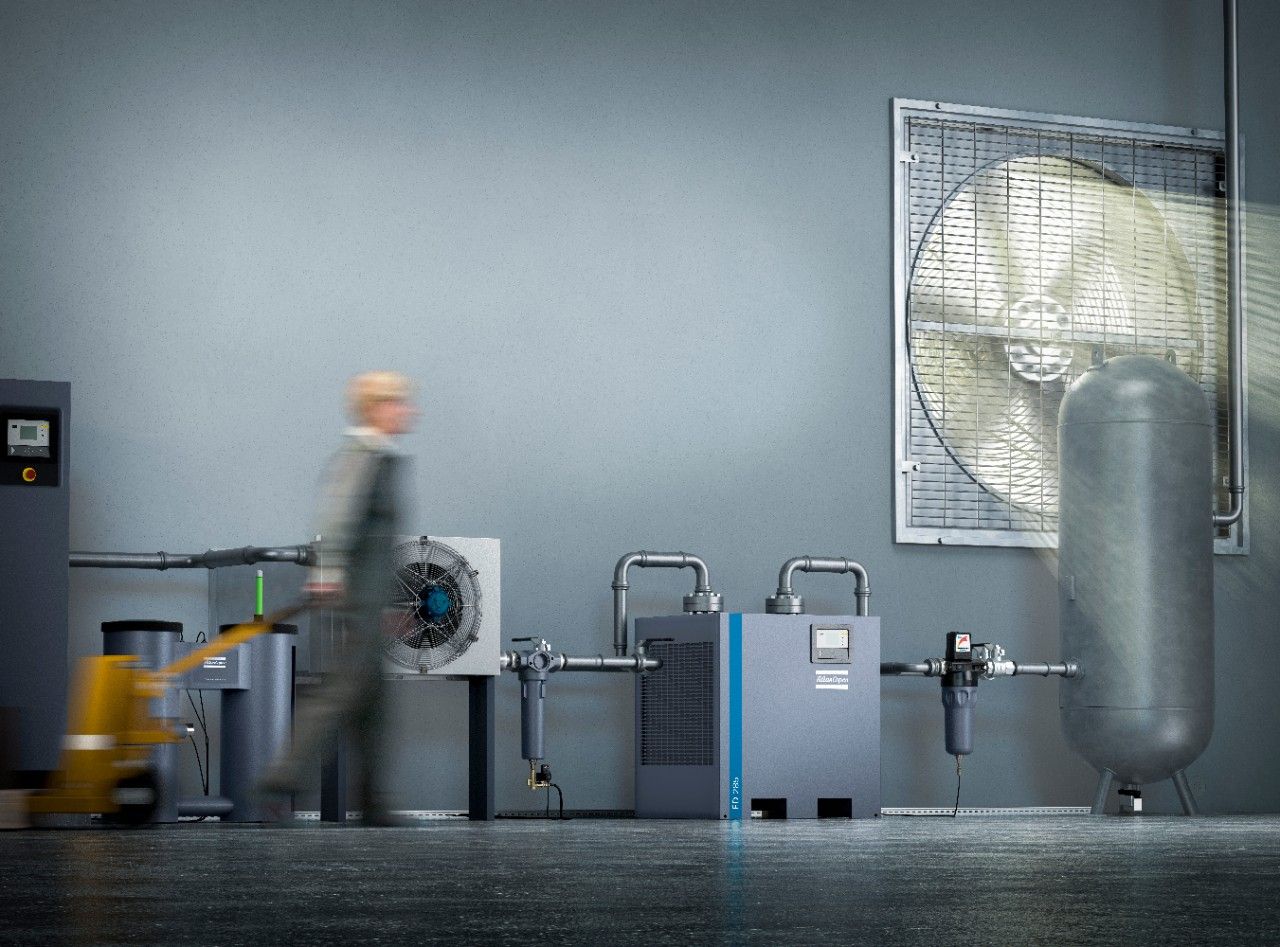

Condensate drains are installed on moisture separators, coalescing filters, air receivers, air dryers, and drip legs to remove this condensate from the compressed air system. The condensate should be piped from automatic drain valves to oil/water separators to remove the oil from the condensate prior to discharge to a drain.

Pay attention, that the drains operate properly. Only in that way the filters and separators are successful in completing their task. Types: (high pressure) Electronic condensate drain, timer controlled condensate drain, automatic mechanical (high pressure) condensate drain, manual condensate drain.