Design + Validation + Documentation

Home/Divisions/Process Equipment and Engineering/Design + Validation + Documentation

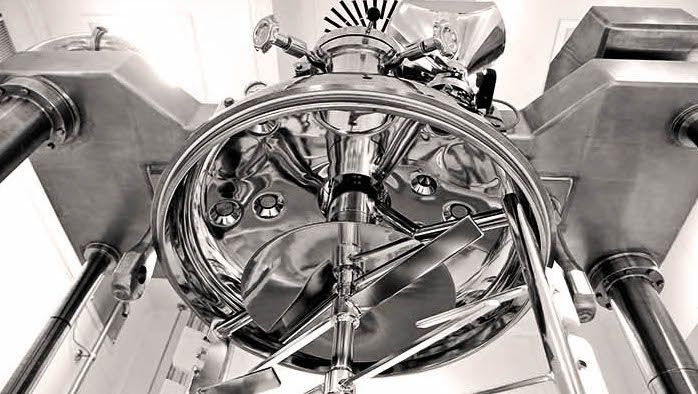

The design of all the above-mentioned processes, the preparation of: basic and detailed designs, specifications of material and labour, URS, 3D modelling, construction, detailed drawings for manufacture, ‘as built’ design/projects, technical documentation, validation documentation, validation execution.

Preparation and execution of projects and equipment according to ATEX.

Automation of all mentioned above including electrical connections, design documentation, technical documentation, and validation documentation and execution.

Process and product safety is always a priority for us.

We ensure compliance with GxP’s and other official requirements (FDA, EMA, etc.) in accordance with current standards in construction and conversion of entire plants or plant components in the pharmaceutical industry.

We aim for the complete and comprehensible documentation of all GMP-relevant processes or process steps and the assistance of our customers beyond project completion.

An overview of our services:

- Determining qualifiers

- Risk analysis definition

- Qualification schedule generation

- Implementing DQ, IQ, and OQ

- Extending qualification phases with FAT and SAT

- Assisting in PQ

- On-site operator training

- Formulating SOPs

- Change control

Years of experience, continual further training, and know-how in pharmaceutical plant construction ensure that qualification will be treated extensively and with the utmost quality.