Solutions and Suspensions Preparation

Home/Divisions/Process Equipment and Engineering/ Solutions and Suspensions Preparation

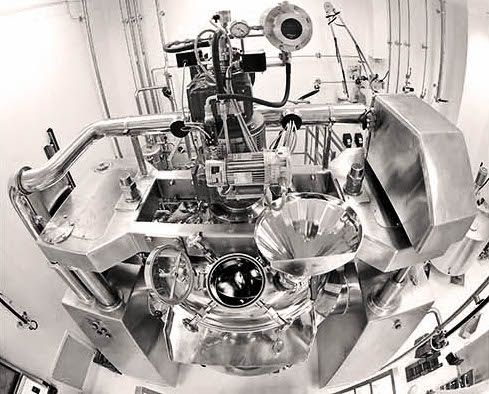

Our systems optimize these operations, which are vital to a final solid- or liquid-form pharmaceutical process. We provide a range of manual and automated preparation and dosing equipment, creating systems designed to optimize the dosing of ingredients.

Units for controlled and repeatable distribution and dosing of various media (WFI, PW, alcohol, solvents, nitrogen, air, dust…) and solution preparation.

Our dosing units for solution preparation are designed and built ensuring a reliable and repeatable process of dosing. During the switch between the dosing media in the recipe the exact separation between media is ensured by emptying the system with compressed air. Minimal product loss is ensured during the dosing media and recipe switches.

The unit enables a controlled mixing of powders, heating and cooling of the process vessels (part of the H/C systems), mixing with variable speeds (part of the process vessels)… Our units fulfil the strict pharmaceutical norms and we can provide all the necessary validation protocols and documentation in accordance with GMP.

Basic features:

Various capacities, sizes and levels of sophistication depending on the requirements of the process and the user

All parts in contact with the product are made of AISI 316L

Surface roughness up to Ra < 0,2µm

State of the art equipment: Endress & Hauser, Gemü, Dockweiler

Automated process control via Siemens PLC or manual

CFR part 11 reporting

All the required documentation: P&IDs, 3D design, FDS, HDS, SDS, DQ/IQ/OQ/PQ, technical documentation, certificates, statements, ATEX…