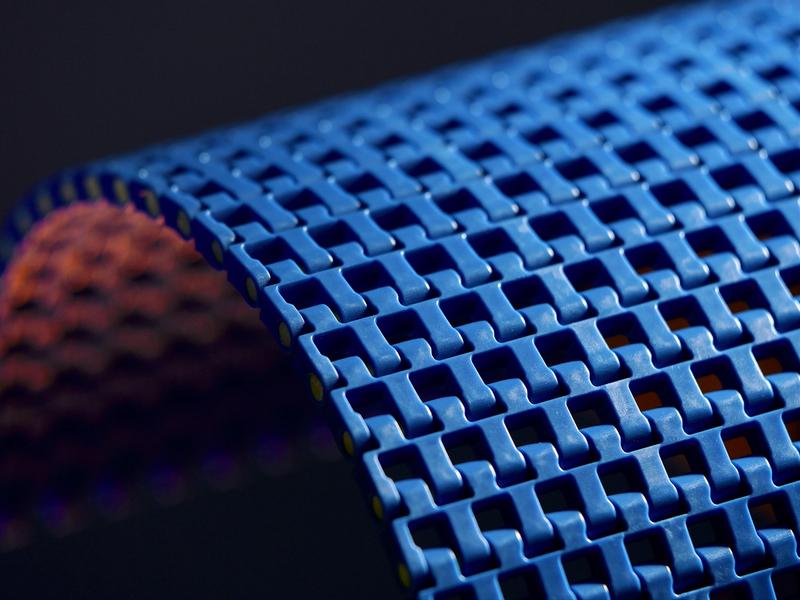

Modular Belts are positive drive, low-noise and long lasting.

Assembled in a bricklay pattern, they can be made to almost any length and width and a wide-range of accessories are available to customise the belt for specific applications or processes.

We are now proud to be able to offer two key modular product brands to our customers.

Discover our wide variety of belts available with varying pitches, openings, surface types, accessories, materials and colours.

- Advanced polymers improve non-stick characteristics, reduce friction and lower power consumption

- Metal detectable, flame-retardant, electrical conductive, high temperature resistant

- Safe conveying for food & non-food items (such as cartons, cans, cars, trucks and even humans!)

Our wide and varied uni Flex Series offer a range of unique properties from hybrid to pinless, from small opening % to the most open side flexing belts on the market.

- Various collapse factors

- Full plastic and hybrid solutions

- Pinless and pinned belts

- High curve loads allowed

- High tensile strength

- Rolling curve frictions

- High wear-resistance

- Exceptional durability and hardness

- High PV limits

- Excellent surface finish

The most trusted name in modular belting, also offers a range of innovative accessories for its Plastic modular belts including:

- uni UltraClean Two-Part Sprocket

- uni UltraFit Two-Part Sprocket

- Pop-up Flight